Define Requirements

We map operational conditions, thermal exposure, and mission objectives to produce a precise requirements baseline.

Thermal protection engineered for aviation, space, defence, and heavy-industrial assets

Our coating architectures deliver heat shielding, erosion resistance, and strong adhesion on metals and composites. Layered stacks enable thermal barrier effects and surface robustness while maintaining lightweight efficiency. Application methods can be tailored for different geometries, coverage and other operational demands.

Exceptional insulation for extreme temperature environments

Optimized material design for weight-critical applications

Superior resistance to erosion and spallation under demanding conditions

Coatings that protect flight-critical hardware in high-demand environments.

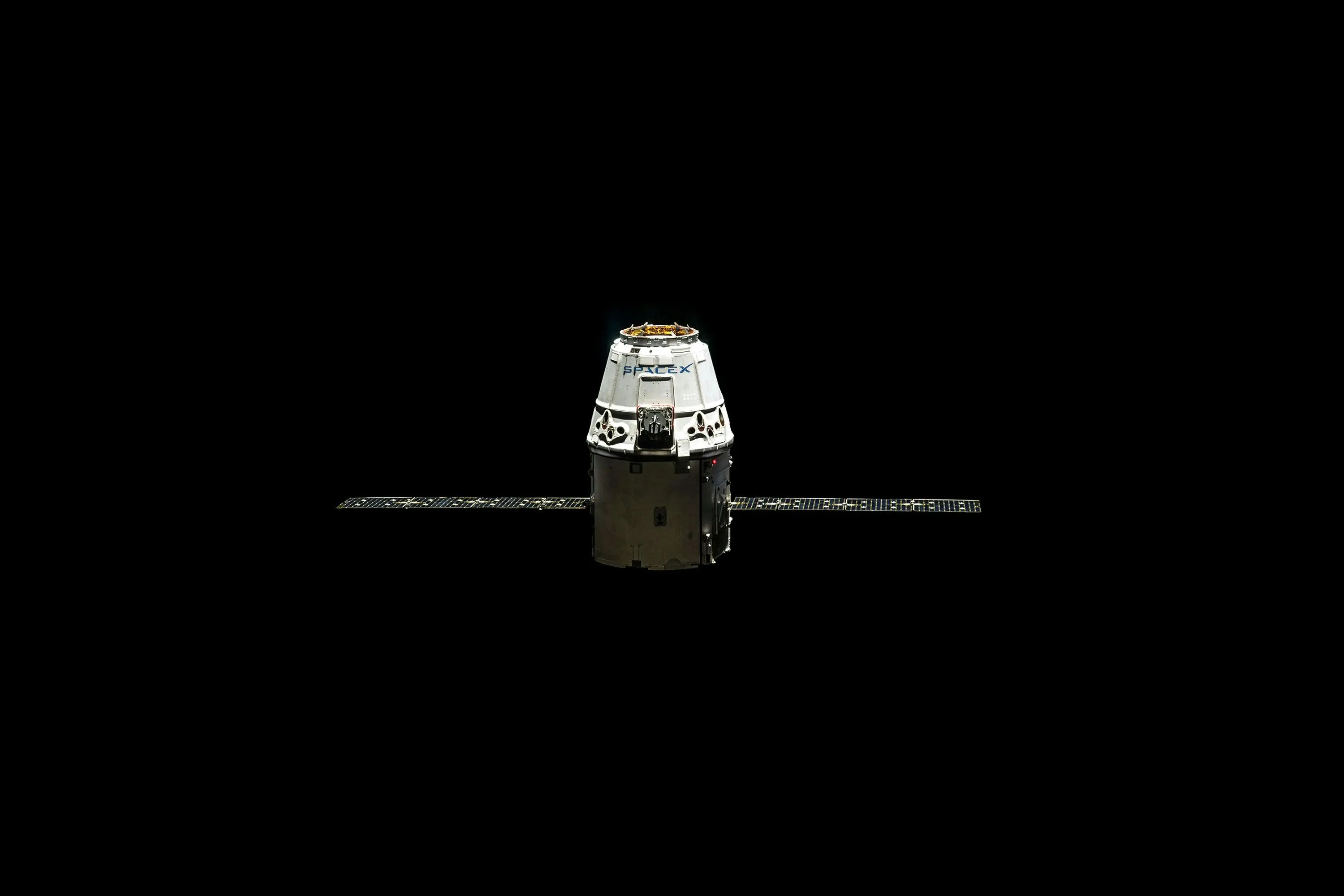

Thermal and surface protection for hardware facing extreme cycles beyond Earth.

Robust coatings enhancing survivability and endurance for mission-critical assets.

Heat-resistant protection supporting efficient, reliable energy output.

Durable surface protection for harsh fluids, loads, and long service intervals.

Coatings that withstand sustained high heat and mechanical wear.

We map operational conditions, thermal exposure, and mission objectives to produce a precise requirements baseline.

Materials engineers architect a coating stack tuned to substrate, thermal load, and durability demands.

Environmental cycling, adhesion tests, and analytics confirm performance under mission-specific loads.

We deploy production-ready processes, QA protocols, and on-call technical expertise to sustain performance.

Align your mission-critical assets with coatings engineered for endurance, safety, and efficiency.

Protecting extreme temperature assets to deliver lower fuel costs, reduced downtime, and improved mission capabilities.

Our solutions reduce fuel consumption by increasing efficiency of your assets. Whether its higher operational temperatures or reducing waste heat, our coatings make it possible.

Our coatings resist erosion and spallation under the most demanding conditions. This reduces maintanance intervals and extends asset lifespan.

Our aim is to be at your side and support your mission-critical asset in surviving the most demanding environments.

Blue Neptune is developing next-generation thermal insulation materials engineered for extreme-temperature and high-performance environments. Our novel coating system is suitable for integration into aircraft engines, rockets, pipelines, blast furnaces, defence platforms, and heavy industrial processing. Our materials deliver exceptional thermal protection, lightweight efficiency, and superior resistance to erosion and spallation; enabling improved performance and survivability in mission-critical assets. As a UK-registered deep-tech startup building a global brand, we are keen to explore collaboration opportunities. Please reach out to us with your requirements.